After vaccines are manufactured, they are shipped to different countries, cities, and communities to reach the people that need them. Some of these journeys are longer than others, and it’s critical that vaccines remain potent while in transit.

Vaccines are temperature sensitive, with most requiring storage between 2°C to 8°C (36°F to 46°F) to maintain potency. If these vaccines are exposed to temperatures above or below the recommended storage range, they can be damaged and potentially leave vaccinated individuals at risk of disease.

This is why it is essential to maintain an appropriate temperature during vaccine storage and transport.

An invisible problem

Over the past two decades, great progress has been made to ensure vaccines are protected from heat damage. For example, PATH helped develop vaccine vial monitors—little stickers placed on vials that flag if the vaccine is heat-damaged.

But progress to protect from freeze damage has been slower, and freeze damage is rarely visible.

Sixty-five percent of routine immunization vaccines are freeze sensitive. In 2020, the United Nations Children’s Fund (UNICEF) procured approximately US$1.4 billion worth of vaccines for immunization programs (not including COVID-19 vaccines), of which more than $943 million worth were freeze sensitive.

In particular, vaccines containing aluminum adjuvants—such as diphtheria-tetanus-pertussis and human papillomavirus vaccines—are freeze sensitive and have high production cost. To reach remote communities in low- and middle-income countries, health workers carry temperature-sensitive vaccines inside vaccine carriers with ice packs.

However, if the ice packs are not carefully warmed to around 0°C before use, the vaccines are at risk of freezing.

Health workers carry the burden of thawing ice packs (commonly called conditioning), requiring them to wait for the ice packs to slightly thaw before loading vaccine carriers with vaccines.

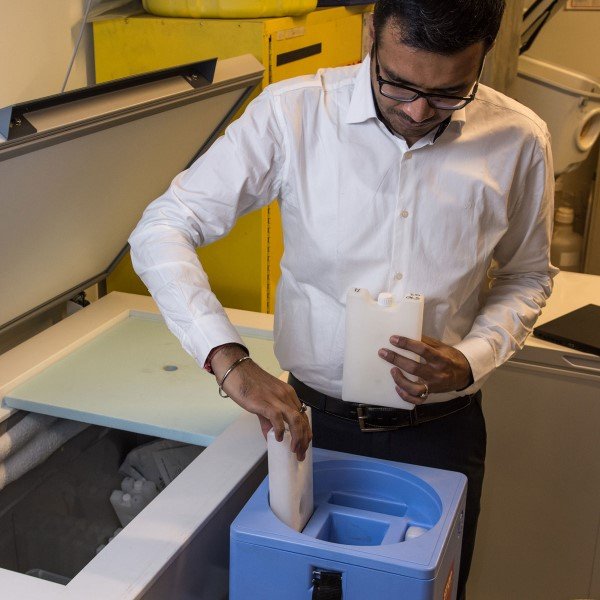

Ice packs can be placed directly into a freeze-preventive vaccine carrier without conditioning them, which saves health workers time and effort. Photo: PATH/Patrick McKern.

Redesigning the vaccine carrier

To address these challenges, PATH started developing the first freeze-preventive vaccine carrier in 2012. The carrier had a redesigned inner chamber that used a thin plastic liner containing engineered paraffin and fatty acid ester–based phase-change material.

The liner, when used inside a standard vaccine carrier, created a buffer between the ice packs and the vaccines to prevent direct exposure to the frozen ice packs. The engineered phase-change material helped regulate temperatures. It successfully kept the vaccines cold, but not too cold.

However, it was too expensive to scale globally.

Working with stakeholders and health workers, PATH’s laboratory refined the design to use a lower-cost phase-change material—water. The new carriers still prevented temperatures from falling to less than 0°C inside the vaccine compartment, successfully preventing vaccine freezing.

This breakthrough solution ensures vaccines remain potent, and thus effective, while eliminating the need to condition ice packs, reducing health worker burden and saving money.

To increase access to the innovation, PATH put the freeze-safe reference design into the public domain in 2016, allowing any manufacturer to incorporate it into its vaccine carrier products. PATH also collaborated with manufacturers in India and China to accelerate the development and production of the freeze-preventive technology.

In 2017, a carrier manufactured by AOV International using PATH’s reference design became the first freeze-preventive carrier to obtain World Health Organization Performance, Quality and Safety (WHO PQS) prequalification. WHO PQS evaluates and prequalifies equipment based on standards and technical requirements before the products can be procured by countries through UNICEF.

As part of the WHO PQS full prequalification, in early 2018, PATH conducted field evaluations of the freeze-preventive vaccine carrier in 24 health facilities in Nepal, in collaboration with the B.P. Koirala Institute of Health Sciences, Dharan, Nepal, and the Family Health Division of the Ministry of Health.

Nepal was selected for the field evaluation due to the country’s varied climatic, topographical, and environmental conditions, as well as the ministry’s interest in conducting the field evaluations.

Results showed that the freeze-preventive vaccine carriers prevented freezing temperatures in outreach vaccination settings and were cost-effective and acceptable, though some health workers found the size and weight of the carriers challenging.

Ensuring long-term, scalable impact

Today, four manufacturers are producing and supplying freeze-preventive vaccine carriers that are WHO PQS prequalified.

To date, 400,000 freeze-preventive vaccine carrier units have been procured across the globe, which will ultimately carry millions, if not billions, of essential vaccines over mountains, deserts, and forests to children and communities across the world.

Health workers in Nepal protect vaccines from freezing during transit by transporting them in a freeze-preventive vaccine carrier. Photo: PATH.

PATH encourages and promotes new manufacturers to develop the freeze-preventive vaccine carrier. There are five prequalified carrier manufacturers with new, innovative designs coming in the near future.

For further information and resources on this topic, contact Dr. Sandeep Kumar at sdkumar@path.org.